Looking for an Industrial Air/Gas Compressor spares and service but scared of….

-

Wrong Spare Parts Supplied Incorrect spares cause repeated failures and rework.

Loss: ₹25,000–₹1,50,000 per incident | Yearly Risk: ₹2–12 lakh - Delayed Deliveries Stopping Production (67% plants) Late material deliveries halt production lines and crush output.Loss: ₹1–4 lakh per day | Yearly Risk: ₹10–50 lakh

- Slow or No After-Sales Support (93% businesses)Service delays leave compressors idle for hours or days. Loss: ₹50,000–₹2,00,000 per hour | Full Shutdown: ₹5–10 lakh/day

- Duplicate / Substandard Spares (30–40% market)Fake or low-grade parts cause overheating, early failures, and damage.Loss: ₹50,000–₹10 lakh | Airend Failure: ₹3–8 lakh

- Compressor Failing After Service (37% cases) Wrong oil, poor commissioning, and non-OEM spares cause early breakdowns.Loss: ₹1–3 lakh per failure | Yearly Risk: ₹5–20 lakh

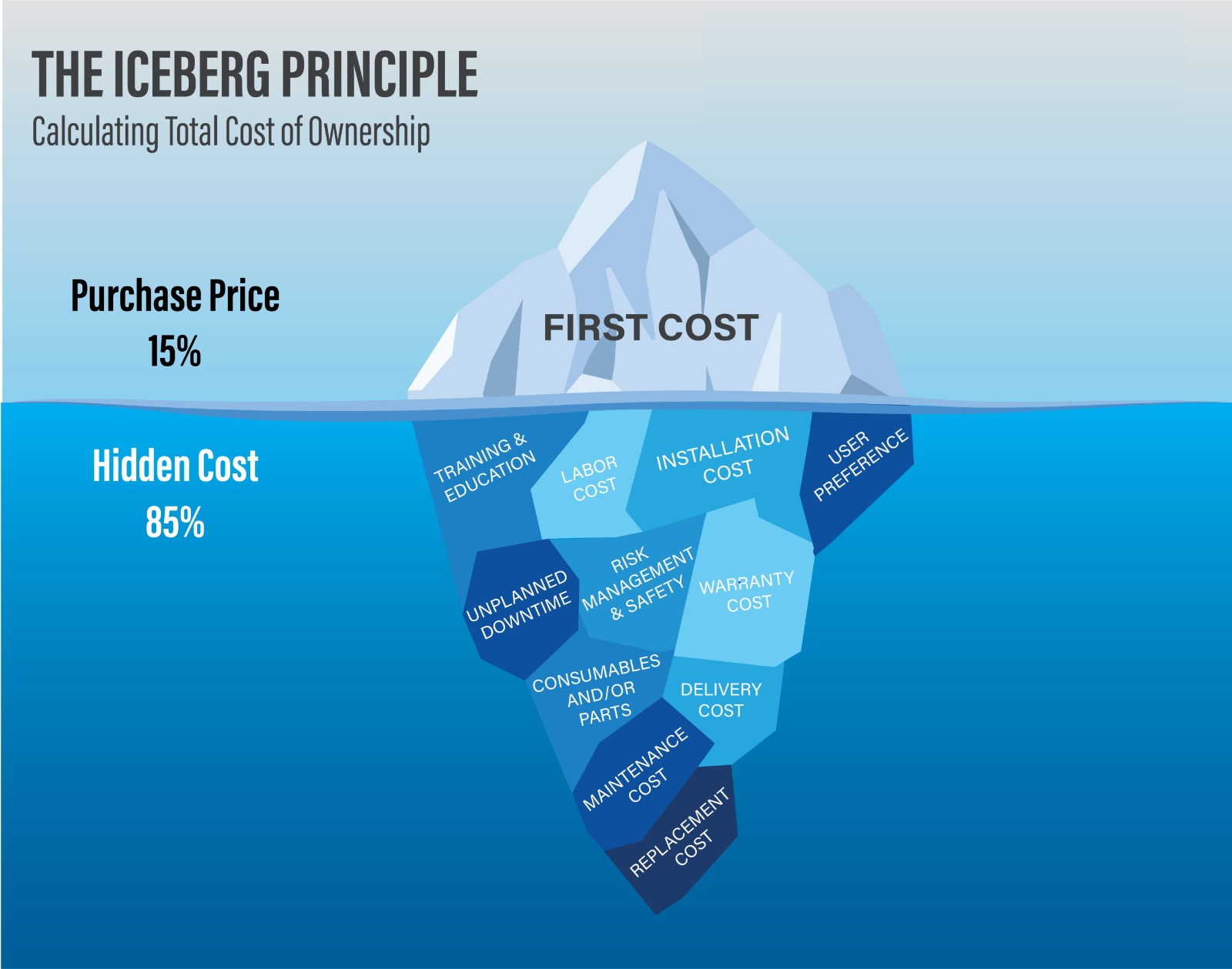

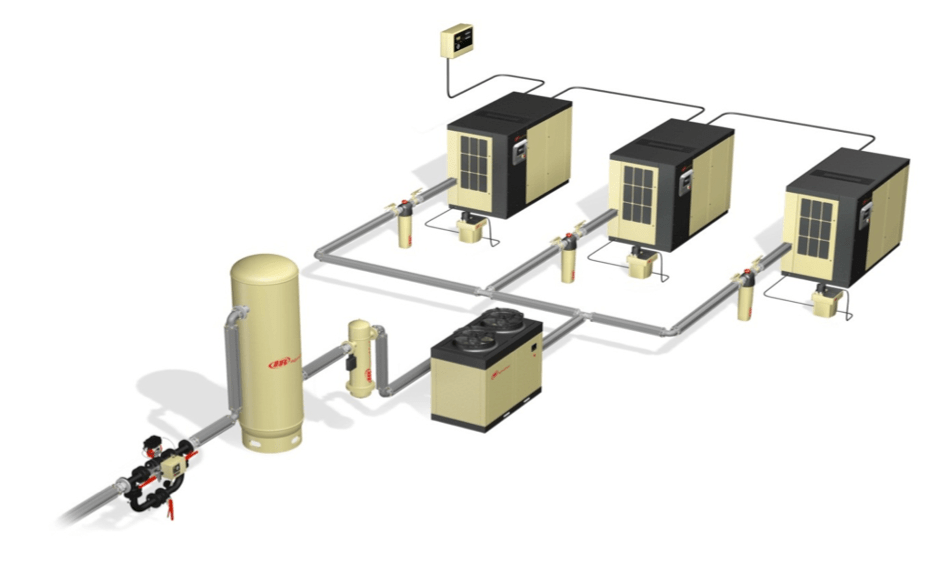

- Energy Wastage Due to Inefficient Systems Power forms 70–80% of compressor cost, and inefficiency drains money.Loss: ₹3–12 lakh/year | Large Plants: ₹20–50 lakh/year

- No Technician During Downtime Technician unavailability increases downtime when output is critical.Loss: ₹30,000–₹75,000 per hour | Full Day Loss: ₹7.5 lakh

- No Accountability From Supplier Wrong oil guidance, incorrect parts, and no documentation cause long-term loss.Total Loss Over 3–5 Years: ₹50 lakh–₹2 crore

Talk to our experts today!

Book your FREE Health Checkup & Audit — our experts will inspect all these issues

Why Choose Utility Engineers Services

Trusted by

Serving

Enabled over

crore in additional client revenue through improved uptime & performance

Saved clients

15 TIPS FOR IMPROVING AIR COMPRESSOR PERFORMANCE Every Maintenance/Plant Manager and Compressor Operator must know

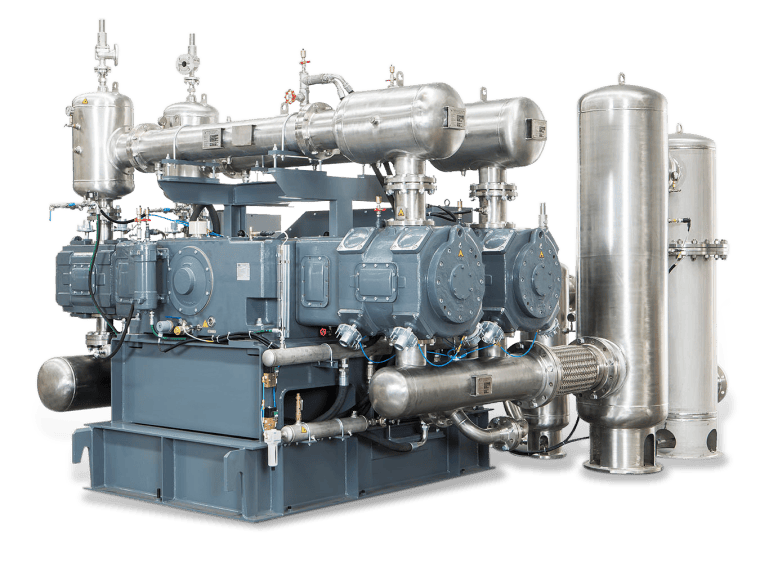

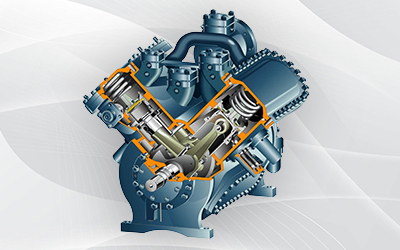

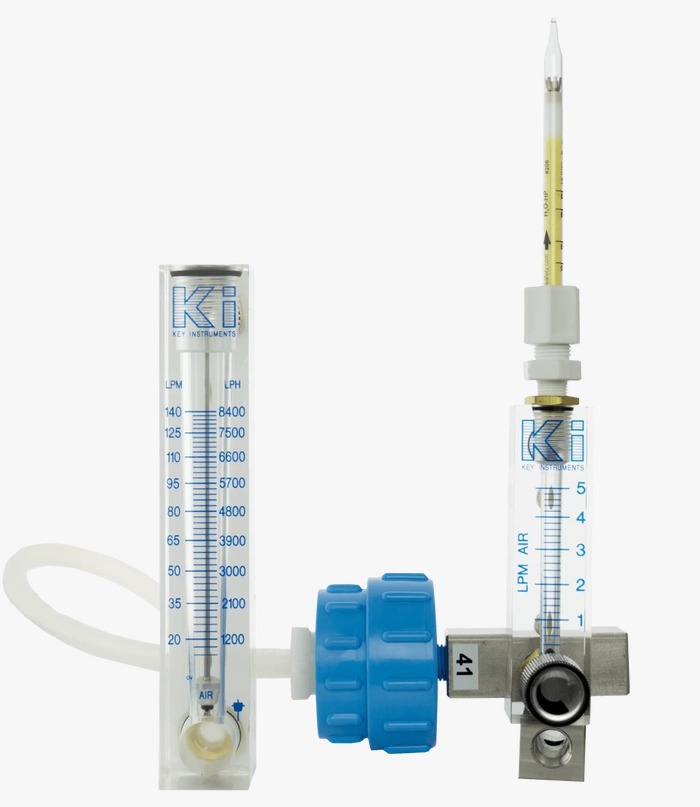

What Products, Parts & Services Does Utility Engineers Offer?

11 Myths About Energy-Saving Industrial Air Compressor Systems That Every Maintenance/Plant Manager and Compressor Operator must know

Key Features & Benefits of Air Compressor Service Agreements

Operational Benefits

- Quarterly Scheduled Service – Detailed appointment summaries document all work performed and highlight recommendations.

- Faster Repairs – Immediate access to stocked consumables and replacement parts ensures rapid turnaround.

- Reduced Downtime – Predictive maintenance reduces unplanned outages.

- Expert Solutions – Certified technicians trained across all major compressor brands.

- Manufacturer & Supplier Access – Choose from multiple manufacturers for the best fit and lowest cost of ownership.

Financial Benefits

- Cost Savings – Efficient scheduling and stocked inventory reduce service costs

- Discounted Service Rates – Lower labor costs compared to standard rates.

- Flexible Payment Plans – Choose from annual (discounted), monthly, or quarterly billing.

System Performance & Reliability

- Extended Equipment Life – Preventative maintenance extends compressor lifespan.

- Precision-Tuned Performance – System optimization ensures energy efficiency and peak operation.

- Compliance & Warranty Protection – Stay within manufacturer warranty terms.

7 Horrible Mistakes You’re Making in Air Compressor Selection — What Every Project, Procurement & Purchase Manager and Plant Owner Must Know

Testimonials

Utility Engineers* has been a crucial partner in maintaining our production efficiency. Their expertise in high-pressure air compressors has significantly reduced our downtime, ensuring consistent output. Their commitment to service is unparalleled.

Reliability* is paramount in our operations, and Utility Engineers consistently deliver. Their solutions have not only improved our production flow but also resulted in substantial cost savings on maintenance. We appreciate their proactive approach and technical proficiency.

The team at Utility Engineers* understands the unique demands of our industry. Their comprehensive service and high-quality spares have helped us optimize our compressor systems, leading to noticeable improvements in our operational efficiency.

In the critical field of oxygen production, reliability is non-negotiable. Utility Engineers has provided us with robust and dependable compressor solutions, ensuring our operations run smoothly and safely. Their support has been invaluable.

Utility Engineers has consistently met our stringent requirements for high-pressure air systems. Their technical expertise and commitment to quality are evident in the products and services they offer. We value their professionalism and reliability.

Utility Engineers has proven to be a reliable partner in our industrial operations. Their solutions have contributed to increased efficiency and reduced maintenance costs. We appreciate their dedication to understanding and meeting our specific needs.

The robust and efficient compressed air systems provided by Utility Engineers have played a vital role in our production processes. Their commitment to minimizing downtime and providing excellent service is highly commendable.

Utility Engineers has provided us with great support for our compressed air system needs. Their team is knowledgeable, responsive, and dedicated to ensuring our operations run smoothly. We are delighted with their service.

In the power generation industry, reliable equipment is vital. Utility Engineers has provided us with reliable and efficient compressed air solutions, and their team is always available to provide support. We highly recommend them.

If you’re facing similar issues with your Industrial Air Compressor, click here — our team is ready to help you.

Trusted by 500+ Clients Across India

Our Approval and Performance Certificate

8 Dirty Little Secrets About Air Compressor Warranties” Every Purchase Manager, Maintenance Manager & Project Manager MUST Know

Air Compressor Services & Audit : The Hidden Competitive Advantage Most Plants Ignore?

A simple audit can cut energy costs, stop hidden air leaks, improve performance, and reduce maintenance—delivering one of the fastest ROIs.We offer Expert Air Compressor service and solutions tailored to your needs.

Download Brochure

Download Brochure