15 Tips For Improving Air Compressor Performance

Monitoring compressed air performance improves efficiency and drives immediate bottom-line savings.

The advantage of compressed air being viewed as the “fourth utility” is that it’s recognized as essential—right

alongside electricity, water, and natural gas. However, this status also leads to a common problem: compressed air

systems are often overlooked and treated as if they require little attention

The reality is that facilities can significantly improve energy efficiency, reduce environmental impact, and lower

operating costs simply by focusing more on their air compressors and overall compressed air performance. These

improvements translate directly into bottom-line savings.

Below, we outline 15 practical ways to enhance rotary screw air compressor performance, beginning with

selecting the right compressor for your operation.

1. Choose The Right Compressor

Three main types of compressors are commonly used in industrial applications: reciprocating, centrifugal and rotary

screw air compressors. Each has its unique advantages:

Reciprocating compressors are typically the most affordable. They use pistons to compress air—similar to

the operation of a car engine. However, they can only operate at a 50% duty cycle (about 30 minutes per hour)

because they require cooling time. As a result, facilities often need a higher-horsepower reciprocating unit to

match the output of other compressor types. They are also known for being noisy, a concern shared by many

operators, including customers such as Factory Finish Smart Repair, Hubbard Feeds, Strategic Materials, and

Custom Thermoelectric.

Industrial-grade reciprocating compressors that run at a 100% duty cycle are available, but they come at a higher

cost. Fortunately, new compact screw compressor technologies are emerging to overcome duty-cycle limitations,

giving traditional recip users access to the advantages of screw compression.

Centrifugal compressors excel in high-volume applications with steady demand. They use an impeller to draw in air

and a diffuser plate to convert kinetic energy into pressure. These units can produce large amounts of air from a

relatively small footprint and are most cost-effective in high-capacity operations.

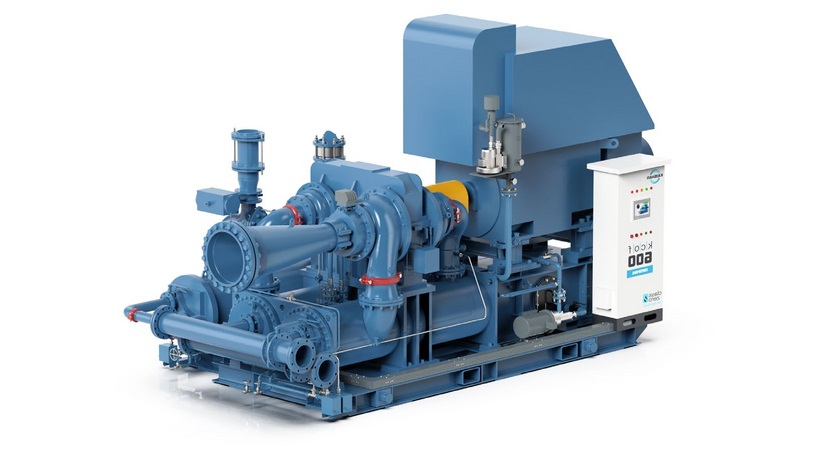

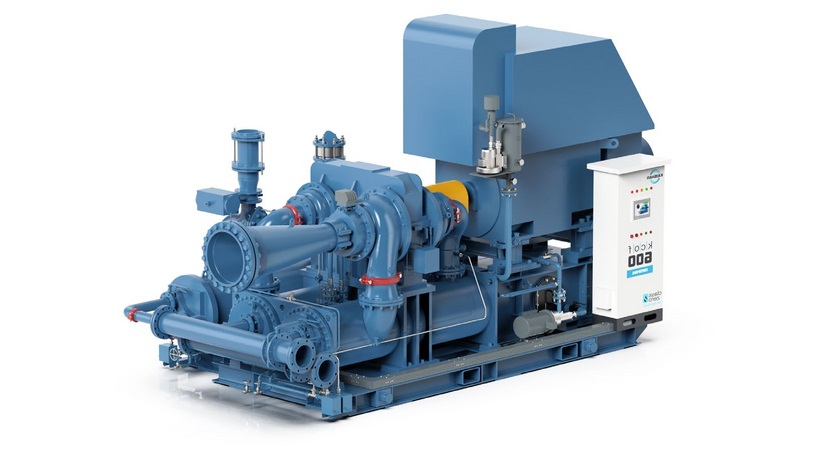

The Utility Engineers air compressor provides a powerful oil-free option, offering superior efficiency, reliability, and support. It features advanced controls, simplified maintenance, and excellent parts availability. All Utility units include proven control and energy-management software for optimized performance.

Utility Engineers compressor ranges from 250 HP and 1,400 CFM to over 10,000 HP and

Utility Engineers compressor ranges from 250 HP and 1,400 CFM to over 10,000 HP and

50,000 CFM.

Rotary screw compressors are ideal for most industrial applications, providing more compressed air per horsepower.

They perform best at a 100% duty cycle and near full load, offering exceptional reliability, long service life, and a low total cost of ownership.

Clean, Oil-free Air

Many applications require high-quality, contaminant-free air—especially in demanding sectors like food and

beverage, electronics, healthcare, and medical device production.

To meet these strict standards, these industries often rely on centrifugal compressors and oil-free rotary screw

systems supported by Utility Engineers’ air compressor services. This ensures consistent, clean, and reliable air

supply for sensitive operations.

Utility Engineers’ two-stage oil-free compressor is an excellent choice when you need clean, highly efficient, and reliable compressed air.

Utility Engineers’ two-stage oil-free compressor is an excellent choice when you need clean, highly efficient, and reliable compressed air.

For a deeper look at the advantages and disadvantages of various compressor types, check out our blog post,

“Which Type of Air Compressor Is Best for Your Application?”

2. Size It Correctly

Sizing may be the most critical decision you make when you’re buying a new air compressor.

It’s more important than the type of machine, whether you’re considering a reciprocating, centrifugal, rotary

vane or rotary screw air compressor.

It’s more important than your decision about the drive system, whether direct or belt-drive. Equipped with a

variable-speed drive. Or whether it’s oil-lubricated or oil-free.

It’s even more crucial than the brand you select. (And how many manufacturers have ever said that?)

The reason? Time and again, experience has shown that the most serious air compressor problems stem from

mistakes in sizing or application.

With rotary screw air compressors especially, that means oversizing. Or over-buying. Trying to add more

“muscle” to your system or anticipate future needs.

It may seem counterintuitive, but with rotary screw air compressors, “too much” is almost as bad as “not

enough.” So, it’s essential that you don’t oversize your system.

Here’s why: Rotary screw air compressors are designed for a 100% duty cycle. Run them significantly less

than that, and you’ll waste electricity.

More importantly, oversizing is the leading cause of rapid cycling, which causes maintenance nightmares,

equipment failures and downtime. We’ll discuss this topic in detail below.

For more information on properly sizing your compressor, see our blog post, “Everything You Need to Know

About Sizing Industrial Air Compressors for Manufacturing.” Or download our white paper, “Demystifying Air

Compressor Sizing.”

The Two Critical Measurements: Cfm And Psig

To size an air compressor correctly, you must understand two key measurements:

-

- CFM represents the volume of compressed air the compressor produces. In international settings, you may

also see flow measured in cubic meters per minute (m³/min), liters per minute (L/min), or liters per second

(L/s). Use our calculator to convert between units. Most equipment specifies the required CFM directly.

- CFM represents the volume of compressed air the compressor produces. In international settings, you may

- PSIG measures system pressure—the force needed by your end-use equipment to perform its job. Higher

PSIG allows more work to be done with less effort and drives the air flow used by your applications.

Internationally, pressure may also be listed in bar or kilopascals (kPa). Again, our calculator can help convert

these units.

To size your compressor, identify the highest pressure required by any device in your system. Then, total the

airflow (CFM) needed by all tools. For example, if you have ten tools requiring 75–90 PSIG and 5 CFM each, you

need a compressor that delivers 90 PSIG and 50 CFM.

This estimate assumes all ten tools operate continuously. If they don’t, apply a use factor to adjust the total CFM

downward. For more detail on determining use factor, see our blog post, “Understanding CFM vs. PSI in Air

Compressors.”

The next major factor affecting compressor performance is the type of control system your compressor uses

3. Choose The Right Controls

The control system is one of the most important elements in operating your air compressor effectively. Over the

years, we’ve found that a well-designed controls strategy is essential for optimizing performance across your

entire compressed air system.

Just as importantly, we’ve gained extensive hands-on experience with a wide range of compressed air control

systems in real-world applications. This gives us a perspective that many of our customers find especially

valuable.

There are two primary types of basic compressed air controls: start/stop and load/no load.

Start/Stop Controls Commonly used on reciprocating and smaller rotary screw compressors (typically under 30 horsepower), start/stop control works much like driving a car. You accelerate to a certain speed—say, 70 mph—then shut the engine off. When the speed drops to 60 mph, you restart the engine and accelerate again. The compressor cycles on and off in a similar pattern

Also known as load/unload or online/offline, this system is found on larger reciprocating units and all rotary

screw compressors. The compressor starts, ramps up to full load, and then shifts into a neutral “no load” mode when it can maintain system pressure without full output.

For more insights into compressed air controls, see our blog post, “Everything You Need to Know About

Compressed Air Controls.”

The biggest challenge your controls face is preventing rapid cycling, our next topic.

4. Avoid Rapid Cycling

Rapid cycling happens when your compressor is constantly turning on and off, loading and unloading.

Here’s how it works: You need pressure, so your compressor turns on. When you reach the pressure threshold, it

turns off. That’s load/no-load.

If your compressor loads before it finishes cycling through to no-load, that’s rapid cycling, and it’s not good.

All of that cycling on and off can be devastating to your compressor, causing:

- Extra wear and tear on the motor, valves, bearings and other internal components

- Overheating

- Carryover of moisture and oil

- Wasted energy

- Increased maintenance

- A shorter lifespan

Compressors have completely burned out after only six months of rapid cycling. It’s basic physics:

Manufacturers will tell you that if a 200-HP motor starts and stops more than four times in an hour, it

will burn out quickly.

For more information, read our blog post, “My Compressor is Rapid Cycling. Now What?”

A variable-speed drive is one of the best ways to prevent rapid cycling.

5. Variable-speed Drive Compressors

Most facility managers already understand the advantages of using variable-speed drives (VSDs) on their air

compressors.

To start, VSDs save energy by lowering motor speed when air demand drops. According to the Compressed Air

& Gas Institute, a VSD can cut energy consumption by roughly 33% and maintain a tight pressure band of ±1.5

PSIG.

They also deliver significant cost savings. A study by the American Society of Mechanical Engineers found that

VSD compressors save an average of ₹1,516.75 per year, with a typical payback period of two to five years. In

addition, many facilities qualify for rebates from state and local governments or utilities.

Utility variable-frequency and variable-speed drives allow rotary screw air compressors to operate more efficiently at part-load conditions.

A variable-speed drive (VSD) allows your compressor to match your plant’s demand profile with maximum efficiency. The compressor uses only the energy required to produce the air you need, enabling smooth adaptation to changing demand throughout the day and keeping the system operating efficiently.

Because a VSD ramps the motor up gradually, it eliminates the high inrush current—often up to six times the

normal operating current—seen in fixed-speed compressors during startup. This reduces peak amps and helps

facilities avoid utility penalties tied to spikes in electrical demand. In short, a VSD ensures your compressor

follows the demand curve as efficiently as possible.

VSDs also help reduce rapid cycling, which occurs when a compressor starts and stops too frequently, leading

to unnecessary wear and potential equipment failure.

These drives deliver the greatest value when a facility experiences significant fluctuations in air demand,

especially in systems that operate between 30% and 70% of capacity. They are ideal for plants with shifting

production schedules or seasonal demand changes. However, they are not recommended for applications

consistently below 20% or above 80% of compressor capacity.

Because they have more significant heat-dissipation challenges, oil-free air rotary screw compressors have a

more limited range for VSDs compared to oil-flooded units. Keeping an oil-free unit in the 60% range is

preferable.

And while VSDs offer a wide range of benefits, there are some situations where they may not be the best

solution. You should probably avoid using a VFD/VSD where you have

- Little to no variation in demand

- An inconsistent power supply

- Excessive dirt, dust, moisture, heat or cold (unless you are using a liquid-cooled VSD instead of a

traditional air-cooled VFD)

We provide more detail on the differences between VSDs and VFDs in our blog post, “How Variable-Frequency-Drive Air Compressors Work” and discuss the pros and cons of VSDs in “The Benefits of Installing Variable-Speed Compressors.”

Most controls, including VSDs, require adequate storage.

6. Include Adequate Storage

Storage is integral to any compressed air system. Air compressor tanks help balance the compressor’s supply of

air with the system’s demand.

As a result, tanks can help accommodate surges in demand, acting as reservoirs during peak times. They also

help remove water from the compressed air system, minimize pulsations in the air flow and ensure smooth

operation.

In addition, a well-sized storage tank can significantly impact energy efficiency. Properly sized tanks reduce the

number of compressor starts and stops, promoting energy conservation and extending the compressor’s life.

CAGI recommends up to 10 gallons per CFM and provides a formula to calculate the air receiver size based on

the time allowed for the pressure drop. The main point is that the tank should be sized to ensure the system does

not cycle more than 10 times per hour

For more information on storage, see our blog post, “A Quick Guide to Accurately Size Air Compressor Tanks.”

Another major air compressor performance issue is understanding the impact of heat.

7. AVOID TEMPERATURE EXTREMES

High outdoor temperatures can significantly reduce air compressor efficiency. When the air outside is already hot, your system must work harder to remove that heat—otherwise performance will drop. Simply put, you can’t cool your equipment effectively with hot air.

Even if temperatures are mild now, heat should remain a key consideration when upgrading or redesigning

your system—particularly since most upgrades occur during cooler winter months.

Heat enters your compressed air system in two main ways:

Ambient intake air

Whatever the outdoor temperature is, that heat comes directly into your compressor. If it’s 100°F outside, your

compressor starts at a thermal disadvantage before the process even begins

Heat of compression

Compressing air naturally generates heat as air molecules are forced closer together. The greater the difference

between discharge and suction pressure, the more heat is produced. Additionally, higher operating speeds generate

even more thermal load.

According to Air Compressor Guide, ambient air entering an oil-lubricated screw compressor at roughly 70°F will

reach 175°F–200°F during compression. Cooling and drying equipment can reduce that temperature, but the

discharged air will still be 10°F–20°F hotter than the intake air.

This means that if your compressor draws in air at 110°F, it becomes very difficult to keep downstream

compressed air below 120°F–130°F—a challenge that can affect efficiency and equipment performance.

And those high compressed air temperatures can:

- Shorten the life of the oil and the compressor itself. Oil life is cut in half for every 10°F you

operate the compressor above its normal operating temperature. - Increase all your costs, including electricity bills and maintenance expenses.

- Make your dryer and filtration systems work much harder, potentially sending water and other

contaminants into your end-use equipment. - Cause problems with applications, like painting, that require high-quality compressed air.

- Contaminate products in contact with that air.

- Damage end-use tools and equipment, degrading lubricants and seal materials.

- Cause corrosion and scale buildup, even resulting in freezing in colder climates, as the water vapor in hot air is released.

For more information on the problems heat can cause, read our blog post, “The Impact of Temperature on Air

Compressor Efficiency.”

Our next topic, installing your system, can help address some heat issues.\

8. INSTALL YOUR SYSTEM PROPERLY

How you install a new air compressor can greatly influence both its short-term performance and its long-term reliability. That’s why it’s essential to do the installation correctly.

Several factors determine whether your installation will be successful: choosing the right location, ensuring you have backup capacity, providing adequate support equipment—especially storage— and confirming the unit wasn’t damaged during shipping. And these are just a few of the considerations.

For a complete list of the key steps to follow before, during, and after installation, see our blog post, “Air

Compressor Installation Checklist—18 Things to Check Before, During and After Your Installation.”

9. PAY ATTENTION TO THE COMPRESSOR ROOM

Proper layout and design of your air compressor room are among the most important factors in achieving a well-performing compressed air system.

When done correctly, a well-planned compressor room improves

- Air compressor efficiency

- Safety

- Quality of the compressed air

- The life of the equipment

- Ease of maintenance

- Return on investment

For more guidance on positioning and planning your compressor space, see our blog post, “Compressor Room Design.”

Another critical performance factor during operation is maintaining system pressure as low as possible to maximize efficiency and reduce energy use.

10. Set Pressure As Low As Possible

A common and costly mistake in operating a compressed air system is misunderstanding its actual pressure requirements.

- You might increase compressor pressure because end users report they’re not getting enough air.

- You may even run your compressors at 125 PSIG or higher to keep everyone satisfied—after all,

no one wants complaints reaching upper management. - You might install regulators ahead of low-pressure tools to avoid over-pressurizing and damaging

equipment. - You may also set all compressors to the same pressure so they can share the load evenly.

If you’re doing any of these things, you’re likely wasting energy. You’re also placing unnecessary mechanical

stress on your compressors, reducing airflow consistency, and increasing the number of system leaks.

Keeping your pressure band tight ensures that applications like spray painting get the consistent air flow they need.

The solution is to set your pressure band and header pressure appropriately.

For a comprehensive discussion on setting your system pressure, visit our blog post, “How Lowering the Pressure Band of Your Compressed Air System Can Save You Money.”

Another key operational issue is reducing overall compressed air demand

11. REDUCE COMPRESSED AIR DEMAND

Reducing demand is a major priority for any facility that relies heavily on compressed air. Lowering artificial

demand not only cuts energy costs and supports sustainability goals, but also extends equipment life and improves overall system efficiency—provided it doesn’t lead to rapid cycling caused by an oversized compressor.

The key is to think of demand reduction as a long-term strategy, not a one-time adjustment. It’s about managing usage smarter, not just using less.

Instead of trying to “win” a one-time battle against excess demand, it’s important to recognize that managing compressed air demand is an ongoing effort. You can learn about the three major factors involved in our post, “Reducing Compressed Air Demand.”

One of those key factors—and our next topic—is fixing leaks

12. FIX LEAKS

The Compressed Air & Gas Institute (CAGI) reports that poorly maintained compressed air systems waste up to 285.51billion in utility costs every year in the U.S. alone. They also estimate that the average manufacturing acility has a 30% leak rate—a staggering amount of wasted energy.

Some leaks are easy to spot because they produce a loud, unmistakable hissing sound. However, 80% of leaks are completely silent, which makes regular leak detection and repair essential.

Leaks can occur for many reasons: improper installation, poor sealing, subpar materials, or damage to pipes,

valves, fittings, and connectors. Human error can also play a role—such as bypassing drains or raising system

pressure during installation or maintenance.

To make matters worse, workers often rely on temporary fixes or quick workarounds to manage leaks. Unfortunately, these short-term solutions rarely hold up and often make the underlying problems even worse.

For a deeper look at the true causes of leaks, visit our blog post, “Eight Causes of Compressed Air Leaks and How to Find Them.”

Ultimately, you can’t truly optimize compressed air performance without using accurate data to measure how your system is performing.

13. MEASURE COMPRESSED AIR PERFORMANCE

Like most advanced machinery today, modern air compressors generate a wealth of valuable data. Leveraging this information can dramatically improve the performance of your compressed air system and your overall operation.

Effectively using compressor data offers several important benefits:

-

- Enhance reliability.Improve the performance of your compressor and supporting equipment such as filters, dryers, and coolers.

- Prevent downtime.Keeping your system operating at peak efficiency helps you avoid costly breakdowns that can damage equipment and halt production.

- Extend equipment life. Detect issues like rapid cycling early, and receive alerts for required maintenance—such as oil changes, sampling, or conditions outside the unit’s design parameters.

- Increase efficiency. Identify factors that reduce system performance, whether it’s an overly wide pressure band or wasted energy caused by rapid cycling.

<li

>Optimize overall operation

- . Fine-tune system settings and align performance with design specifications for maximum output and reliability.

- Maintain air quality. Ensure your compressed air stays within the required specifications for pressure, contaminants, and moisture.

- Adopt strong maintenance practices. Like any other equipment in your plant, air compressors need periodic attention. A data monitoring system can alert you when maintenance is due. Proper maintenance pays

off through better performance, improved reliability, and reduced downtime—and it allows you to schedule

preventive service before small issues become major problems. - Meet regulatory requirements. State and local regulations often require routine system checks, such as tank inspections. Manufacturers may also mandate procedures like oil sampling to maintain warranty coverage. Effective monitoring helps you spot problems early, avoid failures, and prevent accidents that could lead to equipment damage, production loss, or injuries.

- Save money. With reliable data, you can optimize your system, minimize downtime, extend equipment life, and maintain a safer workplace—all of which deliver direct financial benefits.

For more insights, explore the various “Ways To Measure Air Compressor Performance and Know If You Need an Audit.”

The good news is that there are several effective ways to monitor air compressor data—our next topic.

14. MONITOR COMPRESSED AIR DATA

Pneumatic systems have always been well-suited for data collection, and machine builders have taken full advantage of this. Compact sensors embedded in lightweight pneumatic components make it possible to gather performance data from across the factory floor. Even the simplest devices can capture essential information such as temperature, pressure, flow rate, cycle times, valve response speeds, and more.

Today, all of this data can be harnessed to provide unprecedented visibility into your air compressor system—

including the ability to monitor it remotely.

To explore the different data-tracking options available, check out our blog post, “Air Compressor Monitoring Tools for a Smart Factory.”

Our AirWatch system uses a wireless cellular modem to provide real-time monitoring of your air compressor data on any connected device—from desktop computers to smartphones. This solution is a game-changer, eliminating the need to navigate IT approvals, enterprise software systems, or factory automation networks.

15. MAINTAIN YOUR COMPRESSOR

To keep your air compressor running reliably and efficiently, air compressor maintenance must be a top priority.

Industry research shows that a proactive maintenance strategy can reduce maintenance costs by up to 70%.

Regular maintenance delivers multiple benefits—reducing downtime, lowering energy use, extending equipment life, and improving overall safety. Key advantages include:

- Uptime. A study by Industry Week and Emerson reports that unplanned downtime costs manufacturers ₹4,459,157,600 year worldwide. Some estimates show downtime can cost as much as ₹8,02,080.00 per minute. Routine maintenance helps minimize these costly interruptions.

- Safety. Maintaining your compressor reduces risks related to heat, vibration, noise, and airborne contaminants. It also decreases the likelihood of serious failures that could injure workers. Learn more in our post, “Eight Ways to Improve Air Compressor Safety.”

- Equipment life. Proper maintenance extends the lifespan of your compressor and protects the equipment it supports. It also helps prevent catastrophic failures that can lead to expensive repairs or replacements.

- Energy efficiency. A well-maintained compressor operates more efficiently, lowering energy costs. In fact, a compressor’s lifetime energy consumption often exceeds its purchase price. For additional guidance, see our blog post, “Reduce Energy Costs: Four Tips for Plant Managers.

A well-maintained compressed air system also delivers higher-quality air, enhancing the performance and lifespan of your downstream tools and applications.

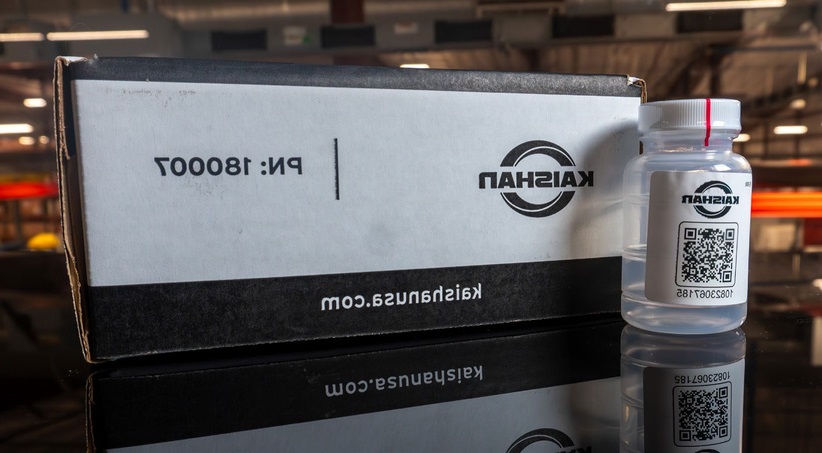

Regular oil sampling is one of the most important maintenance tasks for a rotary screw compressor. Most anufacturers require it to maintain warranty coverage.

For our top 10 essential rotary screw air compressor maintenance tips, read our blog post, “What You Need to

Know About Rotary Screw Compressor Maintenance.”

PREVENTIVE-PREDICTIVE MAINTENANCE

Maintenance programs—particularly those that include both predictive and preventive strategies—can significantly enhance the operation and performance of your compressed air system. Key benefits include:

- Controlling costs. A well-maintained system reduces energy consumption, minimizes downtime, extends equipment life, and helps create a safer work environment—all of which contribute to lower operating costs.

- Reducing unplanned downtime. Unexpected shutdowns are expensive, especially when production

halts and employees are left idle. Proactive maintenance helps avoid these costly interruptions. - Improving reliability. Regular maintenance ensures consistent performance from your compressor and all supporting equipment, including filters, dryers, and coolers.

- Protecting your investment. Air compressors are significant capital assets. Maintaining them at peak performance helps prevent breakdowns that damage compressors, accessories, and end-use equipment—and can even halt plant operations.

- Extending equipment life. Routine maintenance transforms your compressor from a short-term expense into a long-term asset that delivers value for decades.

- Avoiding emergency costs. Proper planning minimizes the need for expensive rush orders, expedited shipping, and overtime labor associated with urgent repairs.

A comprehensive maintenance program that incorporates both preventive and predictive elements can deliver all these benefits and more. For additional guidance, see our blog post, “The Differences Between Air Compressor Preventive Maintenance and Predictive Maintenance—And Why You Should Care.”

GET EXPERT HELP RIGHT IN YOUR FACILITY

Compressed air system operators can do themselves a big favor by shifting their mindset: instead of treating audits as a painful chore, view them as a strategic opportunity to optimize your system and achieve a level of compressed air performance that sets you apart from the competition.

Take our customer Berry Global, for example—a ₹10711.14 billion manufacturer of innovative packaging solutions.

They adopted this mindset and, according to Compressed Air Best Practices Magazine, performed audits at approximately 40% of their plants over the past three years. Some audits led to dramatic improvements in operational efficiency and cost savings. (See our story: “Case Study: Kaishan Centralized Compressor Provides a Huge Savings.”)

An air-compressor audit can deliver significant benefits:

- Save time and money. Critical steps in the auditing process include identifying opportunities to cut energy use and leaks, reduce downtime, optimize system operation, set up comprehensive maintenance program

and introduce new technology. All will save time and deliver significant financial benefits. - Improve reliability. An audit helps uncover issues before they lead to breakdowns and production losses.

- Ensure higher-quality air. By reducing oil carry-over, moisture, and pulsation, you improve the air quality your system delivers—especially vital for industries with strict requirements such as painting, healthcare, life sciences, and semiconductors.

- Extend equipment lifespan. Anything that forces your system to work harder can shorten the life of your compressor, supporting components, and end-use equipment.

- Improve system performance. Even small changes—such as tightening your pressure band or repairing leaks—can produce significant performance gains. Many of these issues aren’t obvious to operators without proper analysis

Ensuring your compressed air system is free from oil carryover, moisture, and pulsations is a critical part of

any audit—especially for sensitive applications such as healthcare.

The good news is that an audit requires little to no disruption to your operation. Once installed, data loggers run quietly in the background, capturing critical information such as airflow, pressure drops, humidity, temperature, and energy consumption.

To learn how your organization can benefit, download our white paper, “How an Air Compressor Audit Can Help You Build Competitive Advantage.” An audit gives your air compressor professional the opportunity to assess your system and recommend ways new technology can enhance performance, reduce operating costs, and improve air quality

Utility Engineers partners with a trusted network of industry specialists who can perform detailed audits and help you maximize the efficiency of your entire compressed air system.

We work with independent, local distributors because they provide nearby access to advanced compressed air expertise. These professionals have the skill and experience to conduct detailed audits and collaborate with you to optimize system performance and strengthen your competitive position.

Unlike large corporate suppliers, our independent distributors eliminate unnecessary red tape. They offer expert guidance, faster response times, and personalized support tailored to your needs. They don’t just sell equipment—they build long-term relationships, ensuring you receive the right system, dependable service, and quick access to parts when you need them.

With factory-trained technicians and deep knowledge of industrial applications, they help you boost efficiency and reduce downtime. When you choose Kaishan, you’re not just buying a compressor— you’re gaining a committed local partner invested in your success.

Leave a message

Leave a message