7 Costly Mistakes in Compressed Air Savings

Compressed air is one of the most widely used utilities in industrial facilities—and also one of the most expensive to operate. Despite this, many compressed air systems run inefficiently due to common design, operation, and maintenance mistakes.

Understanding these mistakes is the first step toward improving system efficiency and achieving real, measurable cost savings

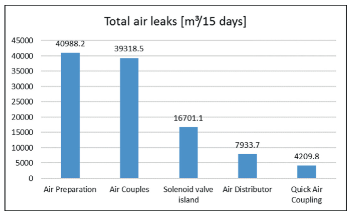

1. Ignoring Compressed Air Leaks

Compressed air leaks are among the largest sources of energy waste in industrial facilities. Even small leaks can operate continuously, forcing compressors to run longer and consume more power than necessary. In many facilities, leaks develop gradually at fittings, hoses, valves, and aging pipelines and remain unnoticed for long periods.

As explained in our detailed guide on how compressed air leaks increase energy costs and impact system efficiency, unmanaged leaks can significantly increase operating expenses and reduce compressor life.

2. Check Plant Pressure

Many compressed air systems operate at pressures well above actual application requirements. Increasing pressure is often used as a temporary workaround for issues such as leaks or restricted airflow caused by clogged filters.

However, running at higher pressure increases energy consumption and accelerates component wear. These effects are discussed further in our article on the hidden cost of high pressure in compressed air systems, where pressure optimization plays a key role in energy savings.

3. Delaying Preventive Maintenance

Reactive maintenance—waiting for equipment to fail before taking action—is one of the most expensive ways to operate a compressed air system. Delayed maintenance often results in unplanned shutdowns, reduced efficiency, and higher repair costs.

A structured approach, as outlined in why preventive maintenance is critical for compressed air reliability, helps facilities identify issues early and avoid costly emergency repairs.

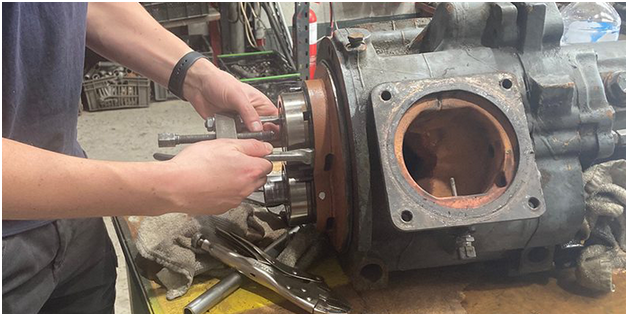

4. Using Low-Quality or Incorrect Spare Parts

Using non-genuine or incorrectly specified spare parts may reduce upfront costs, but often leads to higher long-term expenses. Poor-quality components can affect compressor efficiency, air quality, and equipment lifespan.

Selecting the right spares is essential, which is covered in detail in OEM vs aftermarket compressor spares and their impact on performance.

5. Oversizing the Air Compressor

Oversizing compressors is a common mistake made during system design or capacity planning. While larger compressors may seem safer for future expansion, they frequently operate at partial load, resulting in poor efficiency and higher energy costs.

Proper capacity planning, discussed in how to size an industrial air compressor correctly, ensures reliable performance without unnecessary operating expense.

6. Neglecting Air Treatment Equipment

Air dryers, filters, and separators are critical to maintaining air quality. When neglected, moisture and contaminants enter the system, leading to corrosion, equipment damage, and inconsistent performance.

The importance of proper air treatment is further explained in why air dryers and filters matter in compressed air systems.

7. Never Conducting a Compressed Air System Audit

Many facilities operate compressed air systems without fully understanding how much air is used or where losses occur. Without proper analysis, inefficiencies remain hidden and savings opportunities are missed.

A system-wide evaluation, similar to what is covered in what a compressed air audit reveals about energy losses, provides clarity and supports informed decision-making.

Conclusion

Compressed air savings are rarely achieved through a single upgrade or quick fix. Instead, they come from understanding system behavior, correcting inefficiencies, and maintaining equipment proactively.

Avoiding these common mistakes allows facilities to reduce energy consumption, improve reliability, extend equipment life, and control operating costs.

Leave a message

Leave a message